Anglo American

Evgenii Aleshin

4.00 AM

I am currently living in a house in Middlemount, so it’s important my alarm is set early to allow time to eat and get dressed.

4.30 AM

I start the half-hour drive to Aquila Mine. It is an Automated Longwall UG mine with a life of mine of approx. 8 years. The mine has a relatively low seam with a thickness of only 1.8m.

5.00 AM

I arrive on site. I swipe my card to gain access, today I am not selected for random drug and alcohol testing which means it’s a quick entry to the site. I head to the male bath house to get into my underground work gear.

I also need to get my headlamp and self-rescue. I make sure that it’s in good working order. Then I get my gloves, safety goggles, dust mask, ear plugs and my slam book at the gear station.

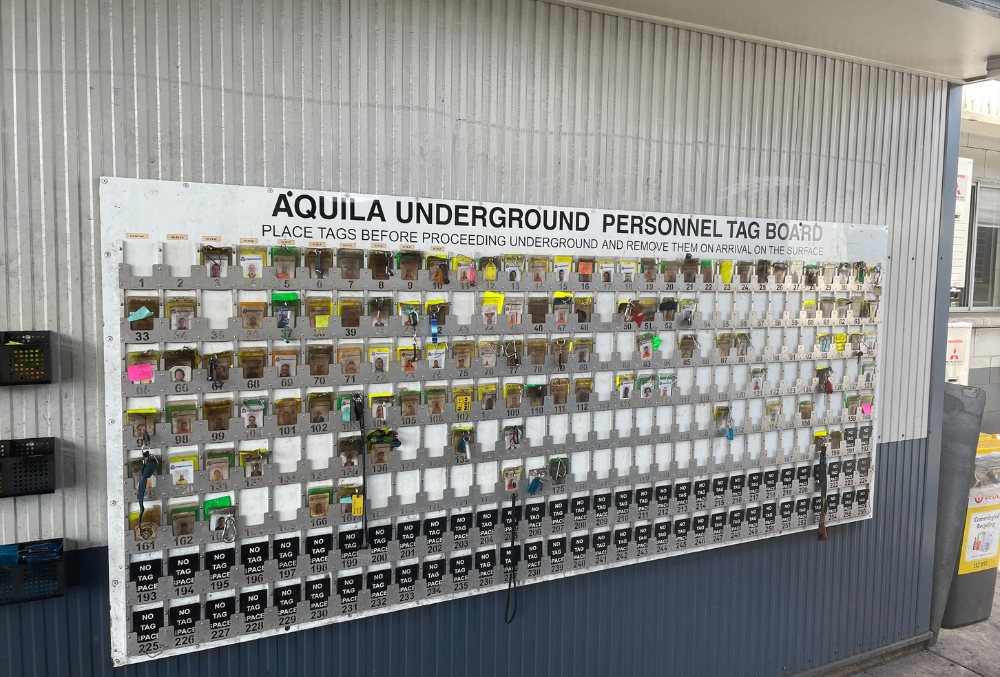

I put my access card on the underground board to keep track of who is underground at any time and what time they are expected to return.

5.30 AM

I am off to the prestart meeting, this is where all the departments (development, longwall, longwall installs, outbye, tech services, engineering) get together and provide any updates before we head off underground. It is a good opportunity for all teams to share the happenings of the previous shift and how we are going with production goals. The meetings ensure everyone is on the same page and we are all keeping safe. Mine Statutory Official (MSO) leads these meetings and makes sure there is a contribution from every department.

6.00 AM

I am heading to the Go Line now and getting into the drift runner. This is my last picture before heading underground as we cannot take any uncertified electronic equipment underground. More safety checks are performed and log books are filled in. After everyone is buckled up, the driver signals to notify everyone about the departure of the vehicle. We get our drift runner fueled up and head off to the first destination point, which is a safety ramp. We stop at the very steep ramp and perform brake checks before we make our way 2 km underground, this takes about 20 minutes due to the maximum speed of 35 km/h that the drift runner can go.

6.30 AM

We’ve arrived at the Crib room where the driver parks up the drift runner. It’s only walking after this point. We need to walk up to a coal face to do mapping and identify geological features such as joints, faults, delaminations, etc. I am working today with Geotechnical Engineer. I get my slam book out and identify any possible safety hazards relevant to my task and how I will mitigate them based on the current conditions. Today we do a group safety slam and it’s signed off by the Deputy of the district. I forgot to mention how dark it is underground, there are no lights here and it takes a few seconds before my eyes adjust after turning my headlamp on. The roof height is low so when exiting the vehicle, we need to be careful not to hit our heads! We start working on the mapping and assessing the geological features there’s lots of walking involved underground and if it's muddy it can make it hard to walk and the gear can get heavy after a while.

10.00 AM

We meet back at the underground crib room and get ready to head back up to the surface in the drift runner. More safety checks are performed before we head off.

10.30 AM

Back to the go line I go to the UG board and remove my card to indicate that I am back from underground, I place back all my UG gear and head for a quick shower.

11.00 AM

I now need to enter in all the data I collected from underground, so I am off to the geotechnical office where I place all the mapping information into the mine plan - we are using AutoCAD it’s a very easy-to-understand system once you get the hang of it. I have been so lucky that all the team have been very accommodating with my questions and have taught me everything I need to know.

12.00 PM

Lunch! I am starving. Today I brought in leftovers from the night before - I love cooking! Spaghetti Bolognaise is my specialty I also keep some extra snacks in the fridge in case I feel like eating more later.

12.30 PM

After a lunch break, I go back to my desk and check my emails. If there is a Permit to Mine (PMT) that needs to be prepared, I go through the documents and make sure that all the information is completed.

3.00 PM

It’s time for a Daily Planning meeting. During this meeting, I and other people from the departments discuss the planning matters for the next 24 hours. We make sure that everyone is aware of what is happening and if there are any activities that might interfere with someone else’s work. We also allocate equipment to various districts such as development, longwall, outbye, etc.

4:00 PM

After a daily meeting, I pass on any important information that was discussed during the meeting that could affect work in the Tech Service department to either geotechnical engineers, ventilation officers, geologists, or gas drainage coordinators.

5.30 PM

I am ready to head home now and start bulk cooking to save some time during my week - did I mention I love cooking?!

7.00 PM

Gym time!!

8.00 PM

The last few hours before sleep I use to wind down. I find watching movies or chatting with my family back home in Sydney helps complete my day.